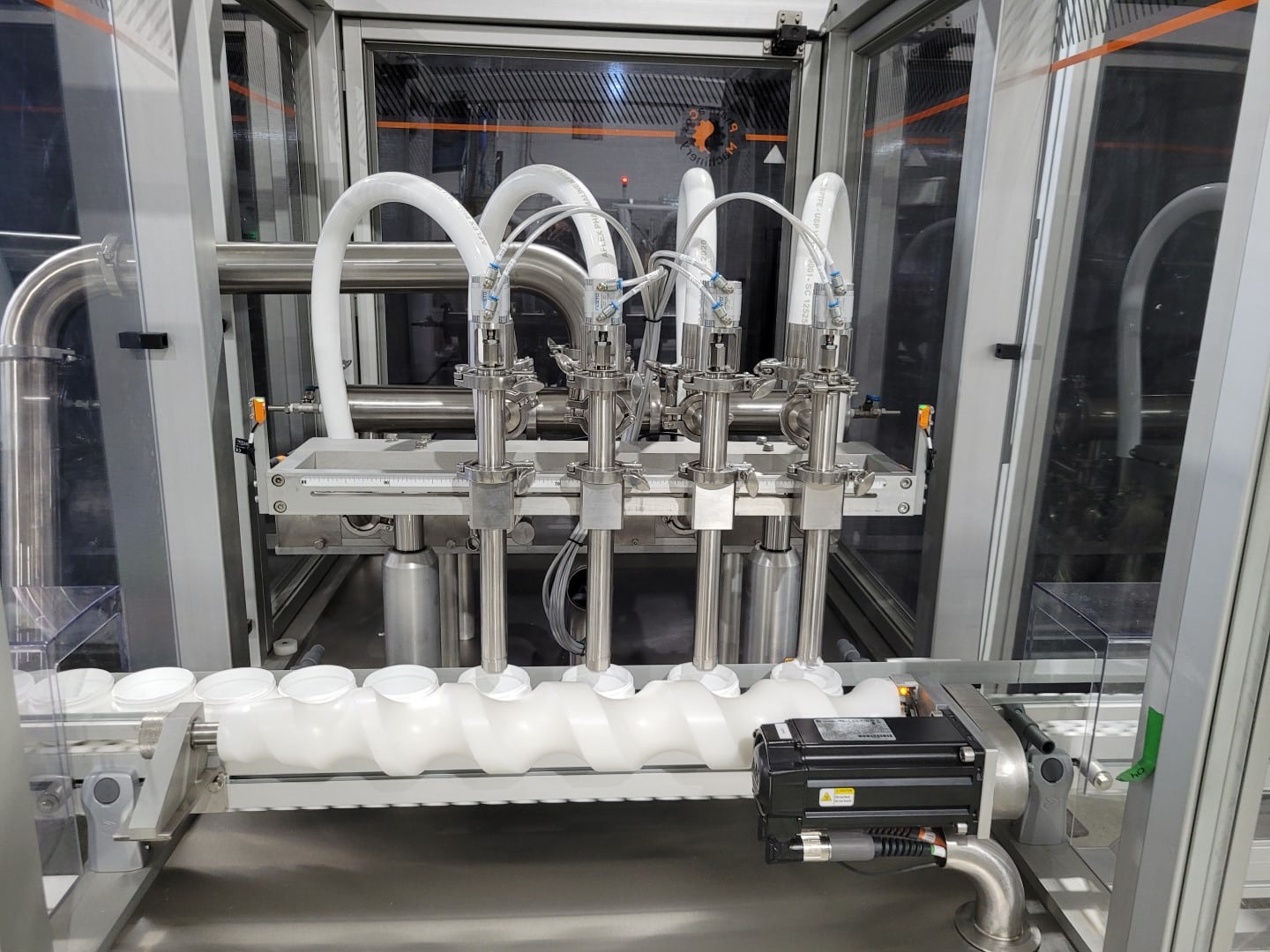

PCM 4 station inline piston filler model RS-FI460

PCM 4 station inline piston filler model RS-FI460, ideal for cream / viscous product, max 60ppm

| Inventory # | REMP-122 |

| Category | Filler / |

| Manufacturer | PCM |

| Model | RS-FI460 |

| Year |

Description

PCM 4 station inline piston filler model RS-FI460

- speeds up to 60 jars/min

- Capable of filling viscous, semi-viscous and liquid product

- Aluminum anodize structure, with bottom panels in S/S 304.

- Base feet for machine height adjustability

- Conveyor included or optional

- Bottle indexation done by pneumatic gate system (optional upgrade to servo worm indexer)

- Validation of # bottles in the filling station done by sensors

- Filling system with bottom-up fill

- x4 Volumetric pistons currently shown with volumetric pistons of 100ml / ea allowing filling between 20ml to 100ml. Precision of fill is approx. +/ 0.5% of the max volume so approx. (.5% * 100ml = +/- 0.5ml)

- Pistons contain o-ring type V special teflon

- Heavy duty nozzle bar with adjustment of nozzle position. Height adjustment of nozzle bar done by servo

- x4 Nozzles shut-off

- Contact parts in SS316 or FDA material

- No hopper is included with filler. PCM includes manifold where client will feed product to filler from client pressurized batch tank. If client requires hopper, PCM can quote separately

- x1 single servo system to drive x4 pistons (optional upgrade to x4 servos for x4 pistons)

- Polycarbonate guards with security interlocks

- S/S electrical panel with Allen Bradley PLC, with HMI mounted in front of machine

- Technical documentation including mechanical, electrical drawings. Operator manual for HMI

- 208V, 3ph, 60HZ, 90PSI